Robot Cells

We make fully customized robotic cells for machine tending and other applications.

GANTRY LOADER

LOADING FROM THE SIDE

We can make gantry loaders up to 6 NC axes, depending on your needs.

In this application, we have 2 trolleys running on a single traverse: one dedicated to workpiece change in the grinding machine, to speed up this operation as much as possible, and one for blowing, palletization, and orientation and length control of the workpiece.

LOAD FROM ABOVE

When cycle time is balanced, a production line can be created by tending different machine tools with a single gantry.

In this application, we unload and load a grinding machine and a lathe in line, picking up and placing machined parts on conveyor belts that we design and supply.

The conveyor belt, with a simple chain adjustment, adapts quickly and without retooling in case of parts of different sizes

BIN PICKING

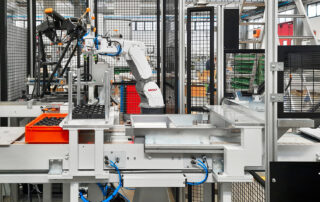

BIN PICKING AND PALLETTIZING

Robotic cell for palletizing: the robot picks up small bulk parts and quickly places them in containers located in the TS2AX tower stocker.

The vision system with structured light technology, mounted on the tower in a fixed position, correctly locates all parts to be picked up.

BIN PICKING AND MACHINE TENDING

Robot cell for picking medium-large size parts from a bin. One robot cares about the picking from the bin and the other of the machine tending in order to optimize the cycle time.

The vision system mounted on a gantry allows to scan with a laser a large area and makes possible to empty the entire bin by identifying the correct grip of all parts.

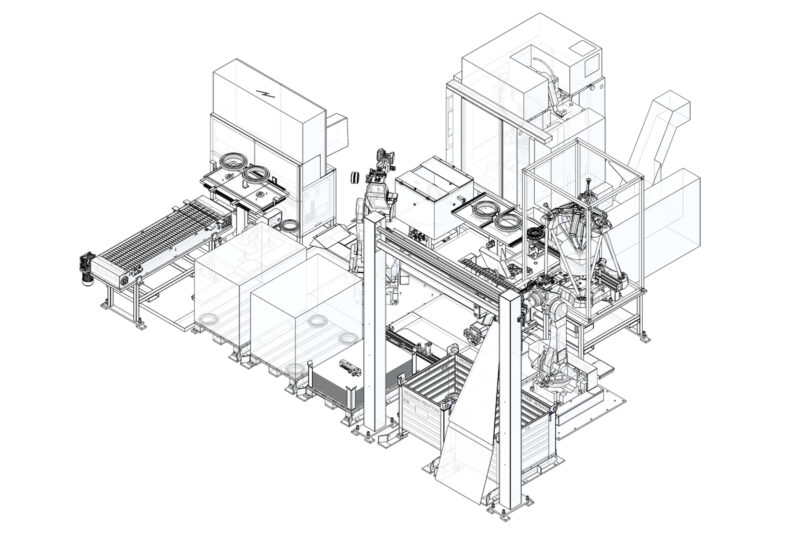

ROBOT ON SLEDGE

ROBOT ON SLEDGE

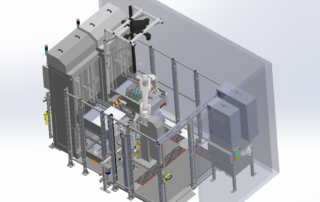

SEVENTH AXIS – ROBOT ON TOP OF THE MACHINE

Mounting a robot on a gantry loader allows to combine the benefits of both solutions: Customers keep the handling flexibility of a 6-axis robot while combining it with the elimination of machine-front encumbrances.

The part feeders proposed in this application allow to manage both shaft type and flange type parts.

Automatic gripper change allows a fully automatic switching from one type of part to another

SEVENTH AXIS – ROBOT ON FLOOR SLEDGE

This solution allows a large work area to be covered with a single robot.

In this case, we have supplied a warehouse with 160 stations for tending a machining center, with codes of various geometries and sizes preloaded on pallets, which are automatically moved by the robot and placed in the machine on 0 points.

ULTRA COMPACT LAYOUTS

ULTRA COMPACT LAYOUTS

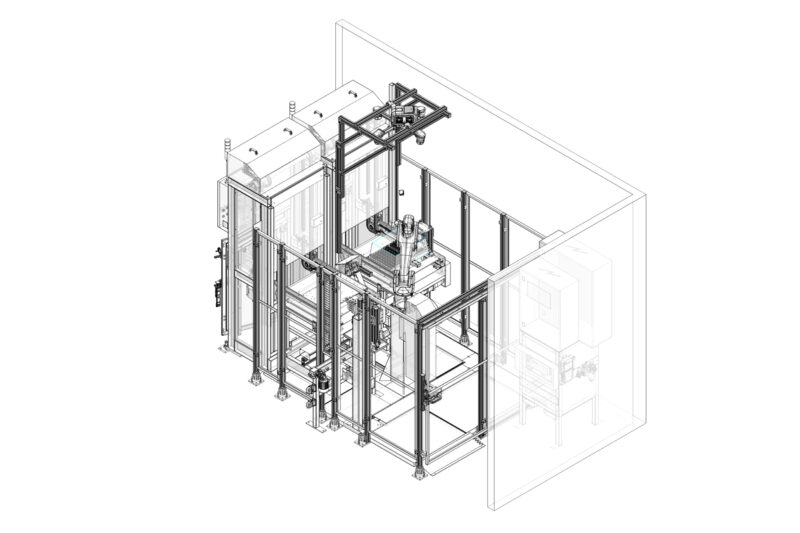

GANTRY LOADER AND TOWER PARTS FEEDER

A solution that almost disappears on the machine tool: the loader moves above the machine, operating from above and thus avoiding any encumbrance in front of the machine; the tower stocker allows a large quantity of parts to be introduced into the robot cell with very reduced footprint due to its vertical development, and allows at the end of the operations to pick up the trolley and transport it with ease to the warehouse, packaging or subsequent processing.

ROBOTS AND PALLETS ON THE GROUND

One of the simplest and most versatile proposals in the machine tending field: the operator places the pallets containing the workpieces to be machined in the work area and picks up the pallets with the machined workpieces. It is also possible to provide solutions with stacked pallets and interleaf management.

The application is suitable for parts of all types and relieves the operator of the repetitiveness and strain of machine loading.

COMPLEMENTARY OPERATIONS

COMPLEMENTARY OPERATIONS

MEASUREMENT BY CONTACT

WASHING – PRESSING

In this application, in addition to the machining tending, the robots are also responsible for measuring and washing the workpiece.

In addition, a bushing-pressing operation is performed in a dedicated station designed by us.

OPTICAL MEASUREMENT

LASER MARKING – WASHING

After unloading the lathe, the robot also washes, measures, and laser marks the part, thus returning a product ready and traceable for the warehouse or further operations.