Parts feeders for robot cells

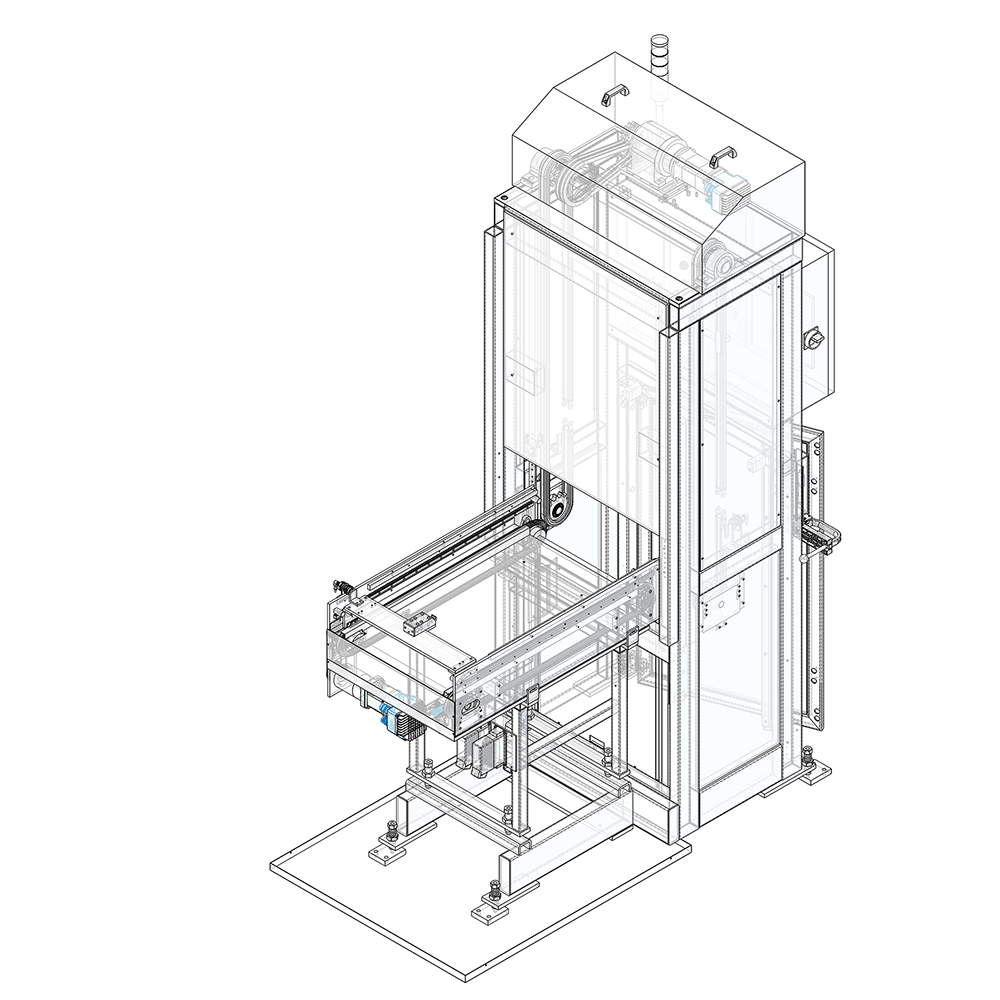

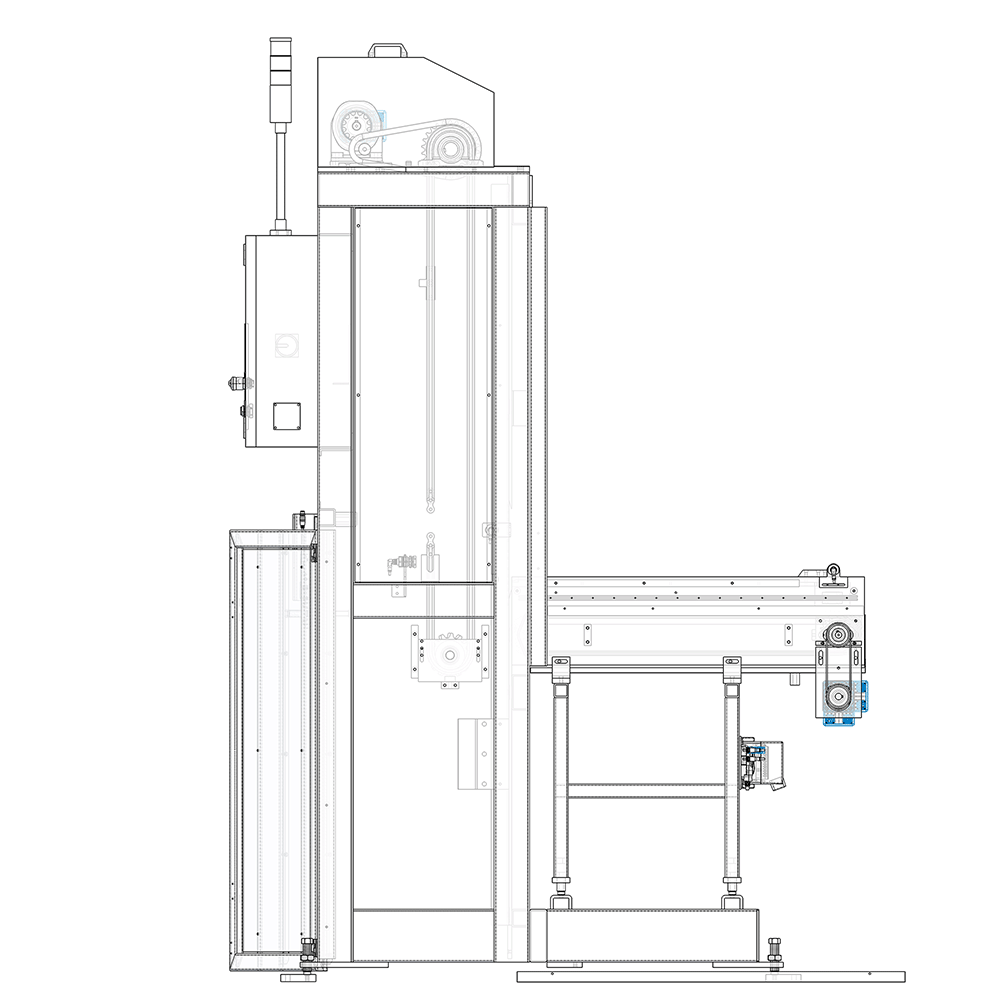

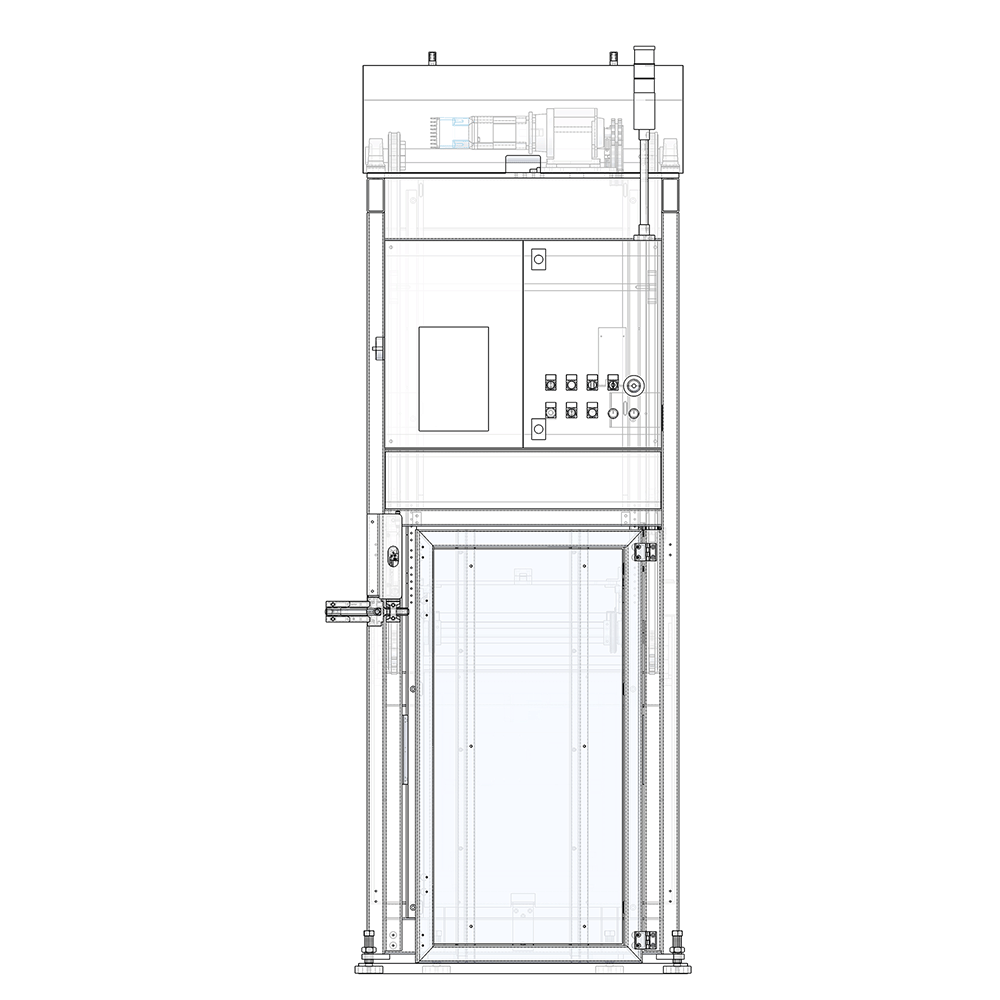

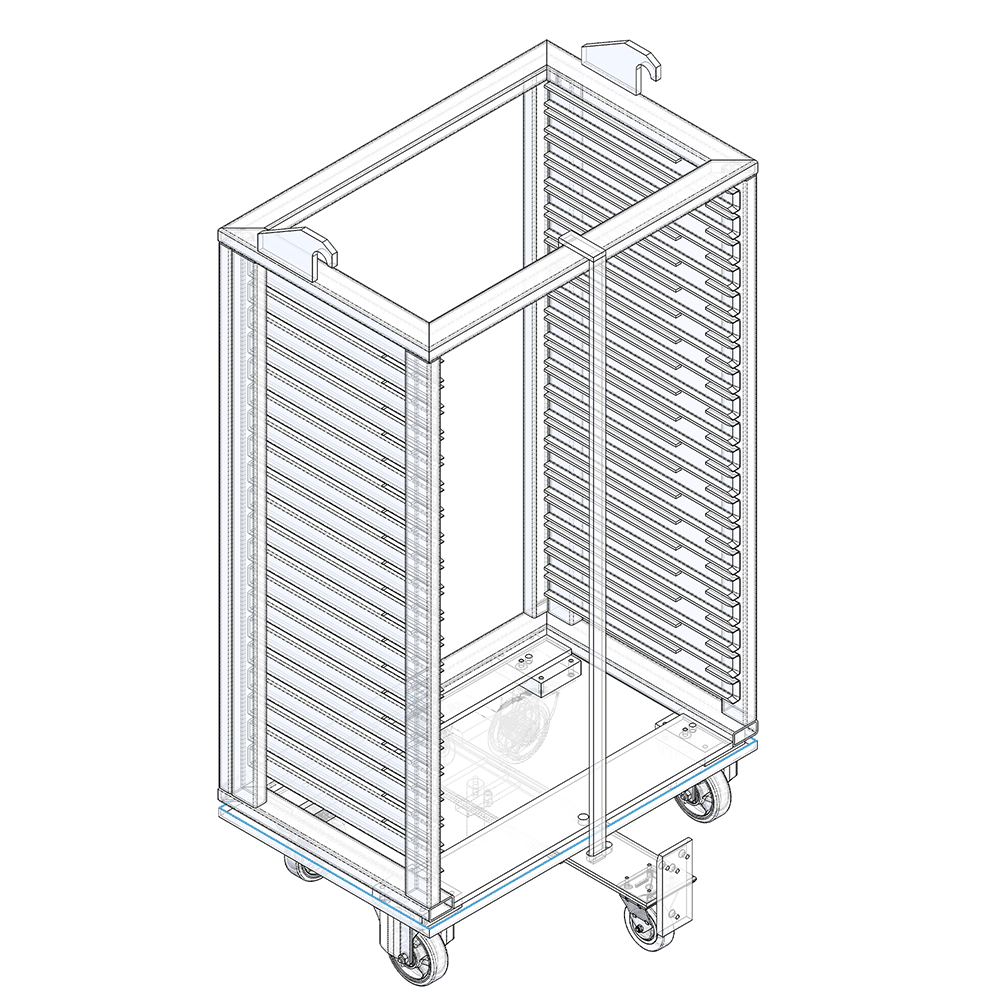

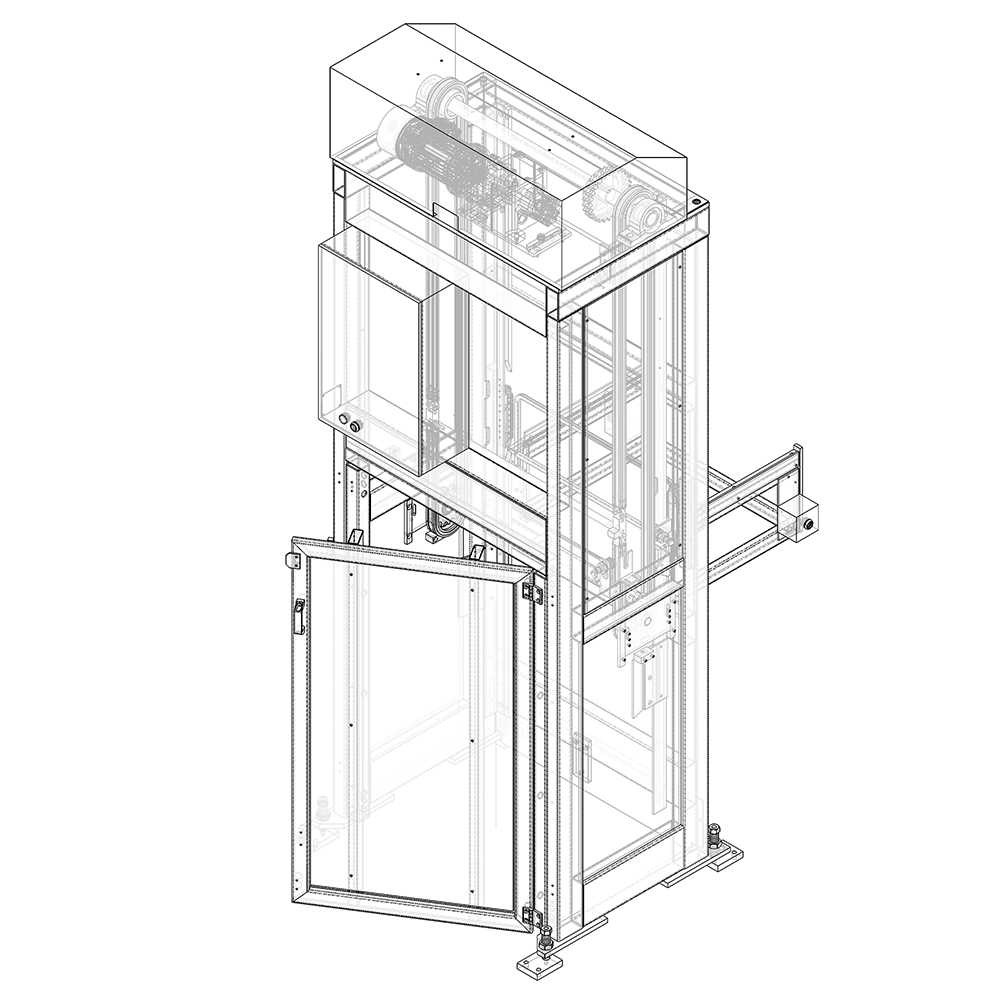

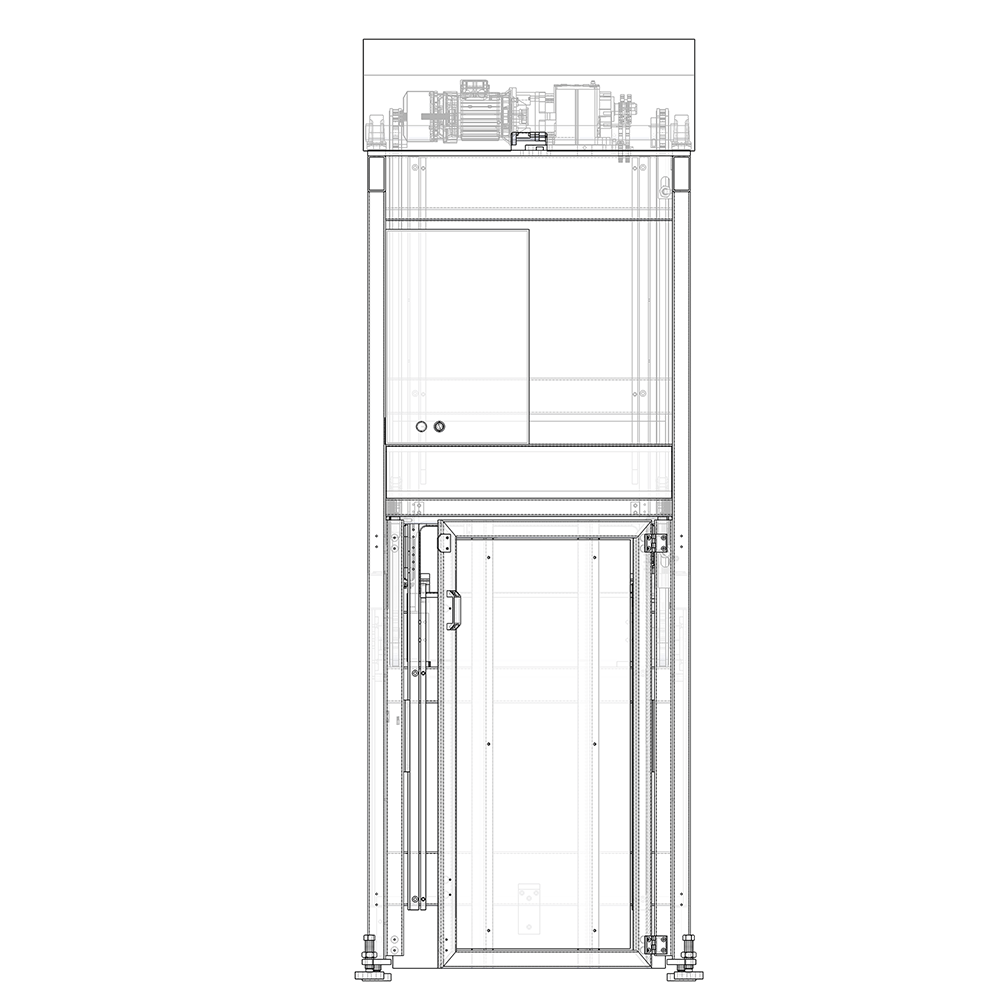

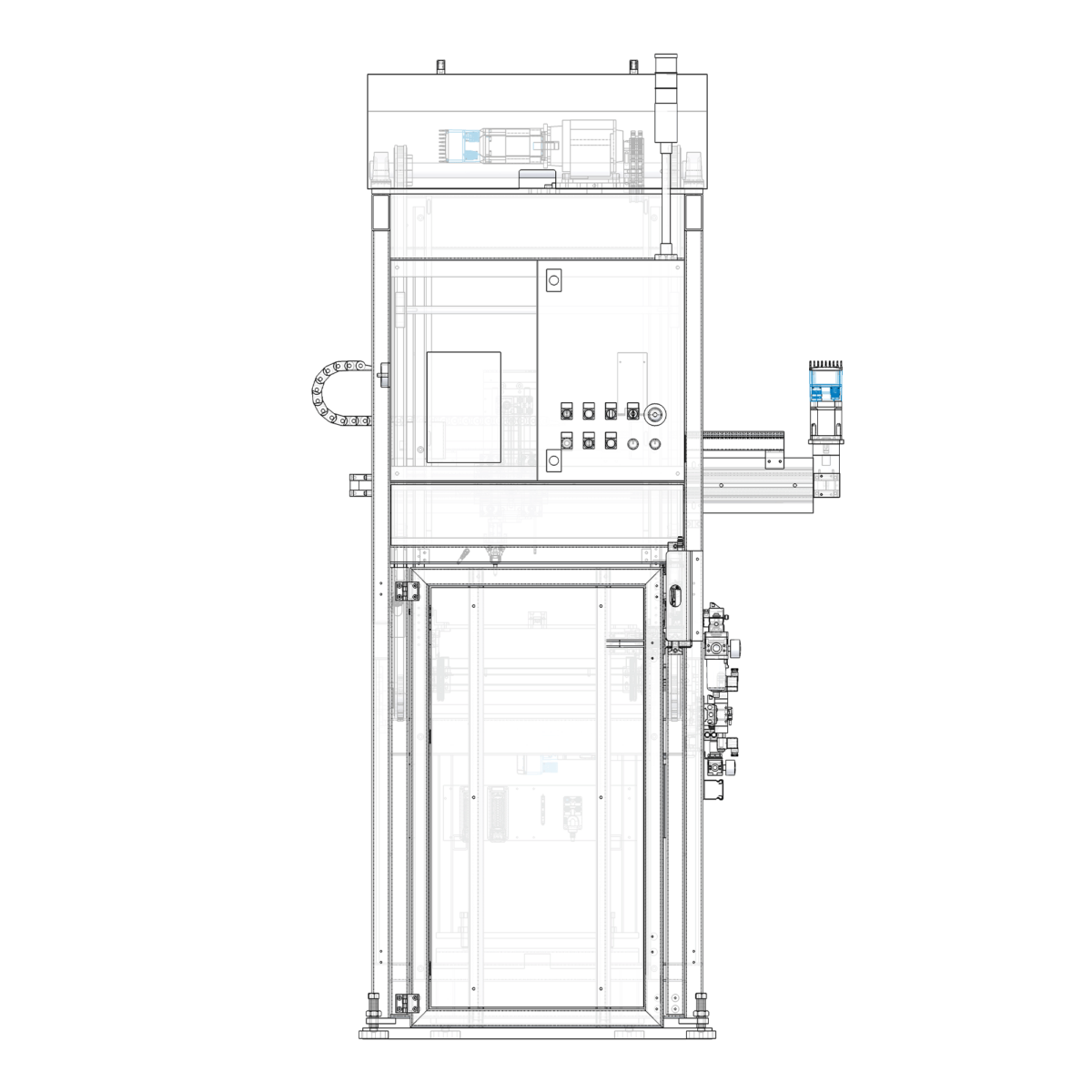

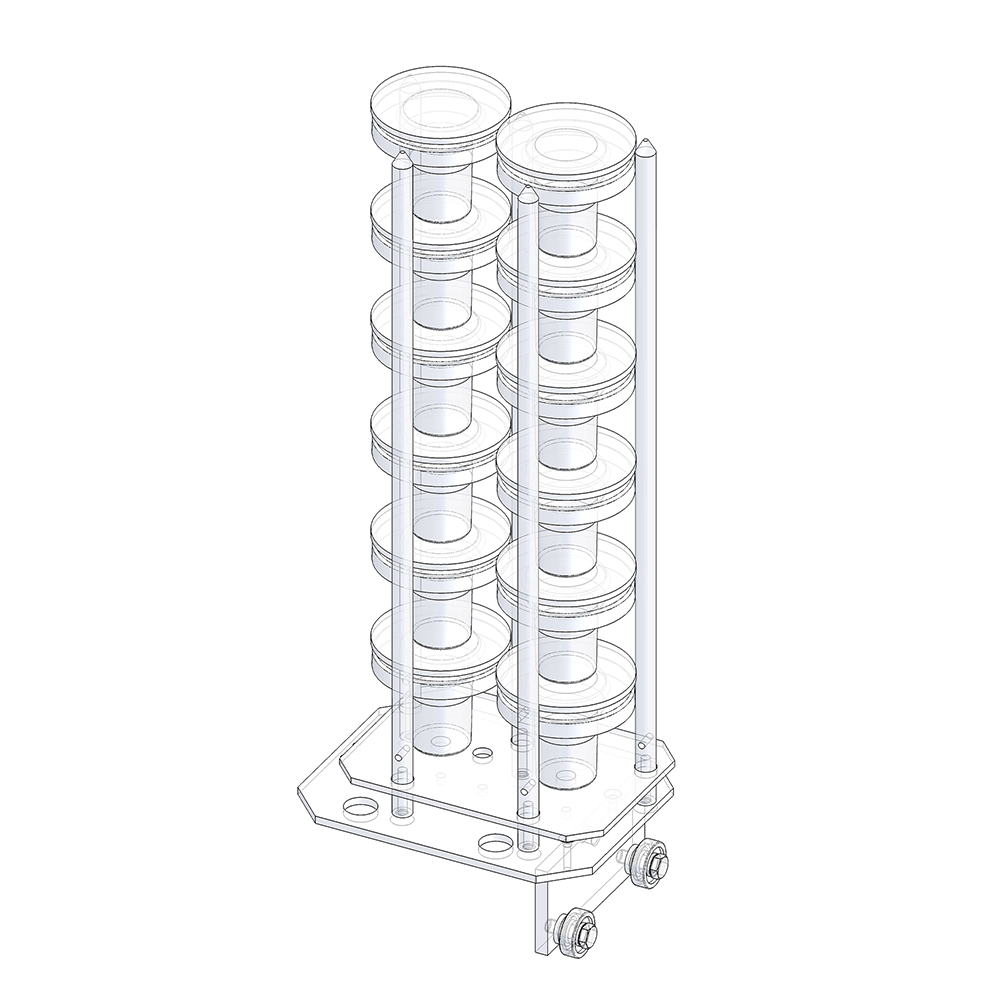

TS2AX TOWER PARTS FEEDER

The TS2AX two-axis tower is a compact part feeder, particularly suitable for small to medium-sized parts. It allows to minimizie footprint in the workshop thanks to its vertical development, and to link different production processes: the operator can transfer the trolley with already machined and palletized parts from one machine to another. The NC with integrated PLC allows management of the 2 main axes, the possible expansion to additional axes and the possibility of interfacing with the most common field BUSes. Pallet extraction by NC allows to match the tower not only with robots but also with gantry loaders. With a dedicated hardware and software package it is possible to manage production lists or specific pallet extraction.

Technical data:

Dimensions: mm.970×1758 H.mm.2700

Max. axis speed “X” (pallet in/out): 30 mt./min.

Max speed “Y” axis (carriage up/down): 3 mt./min.

Power supply: 400V

Absorbed power: 1.5 kW

Weight: 700 Kg

Max. weight on pallet: 30 Kg

Max. weight on trolley: 500 Kg

CUSTOMIZED EQUIPMENT

The mobile trolley and the pallets can be customized for various workpiece types to optimize the autonomy of the robot cell.

It is also possible to load blisters or boxes with already palletized parts.

Pallet size: mm.400×600 h mm.8

Useful trolley height: mm.900

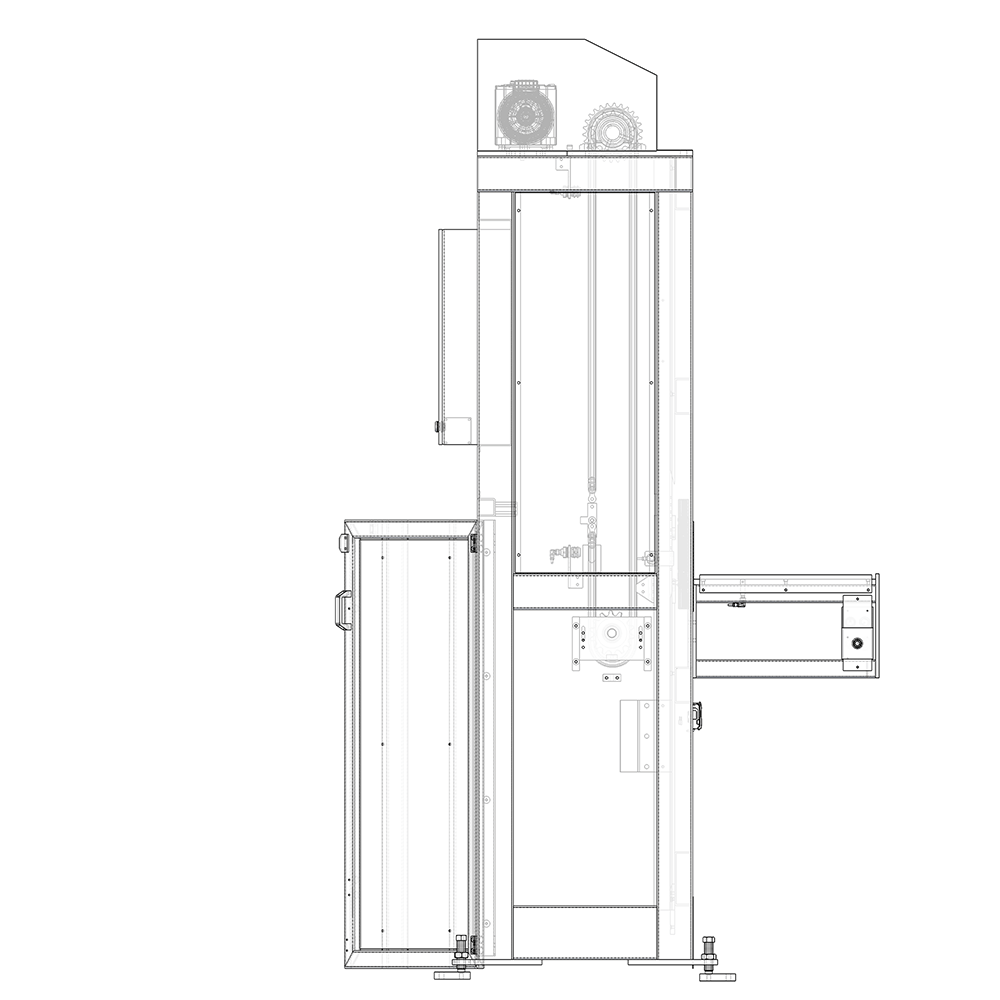

ERGOTOWER LOADING AID TOWER

Ergotower is a piece of equipment for the TS2AX tower parts feeder.

It allows the operator to compose pallets ergonomically, thanks to the motorization that brings the trolley to the correct working height.

The up and down movement of the trolley is operated by two-hand control for maximum safety of use.

Ergotower can be placed anywhere on the shop floor to enable optimal logistical management in preparing parts for production.

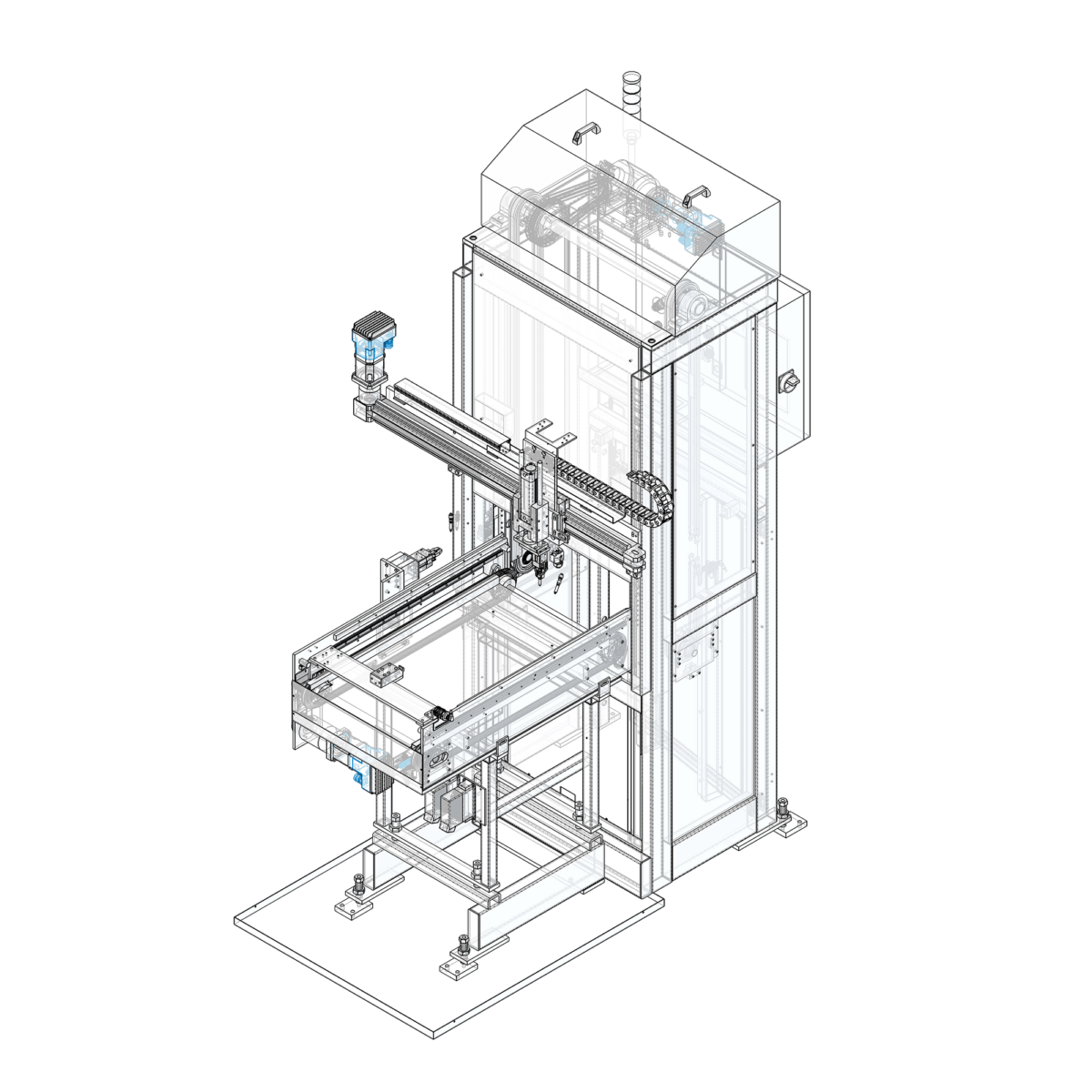

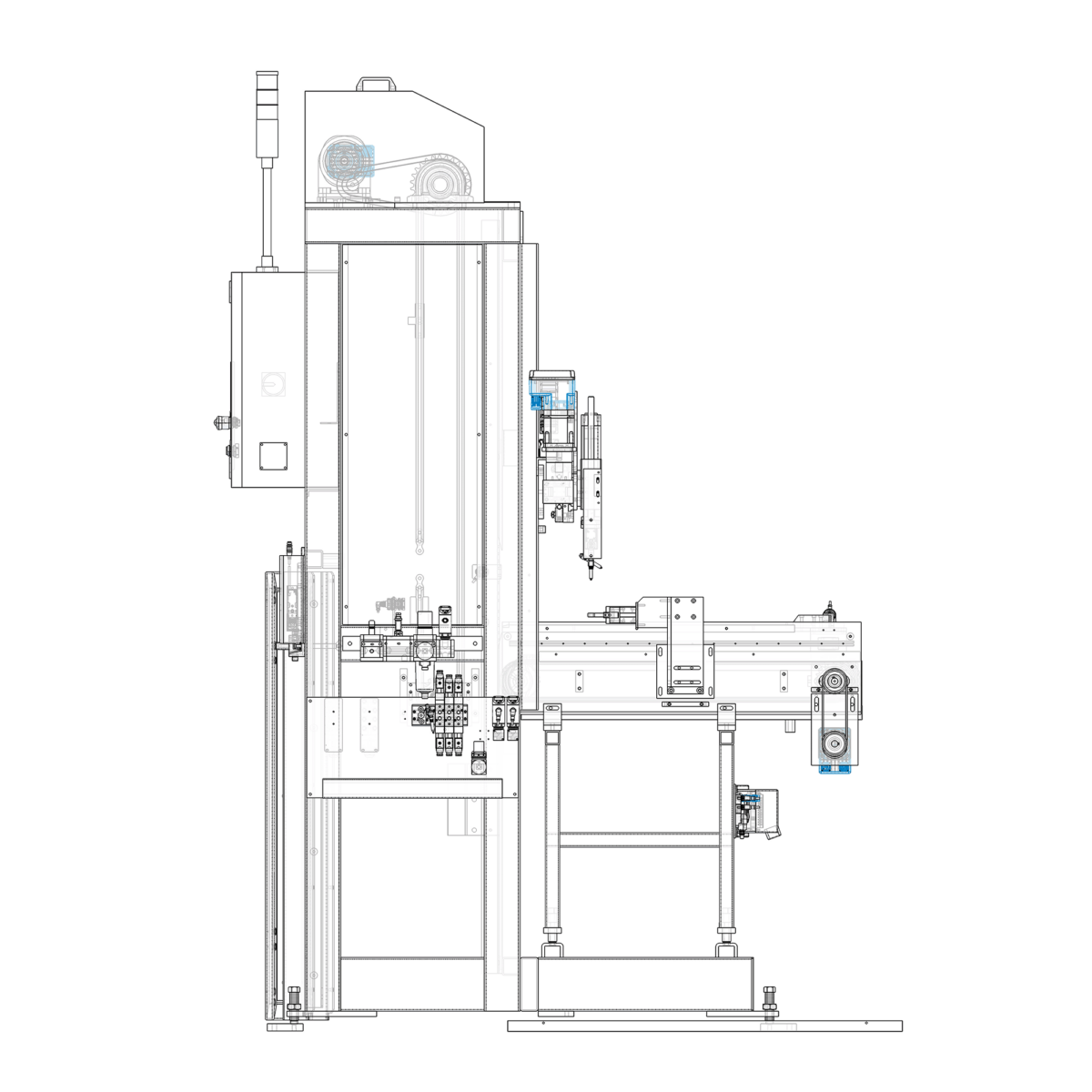

TS3AX- TS4AX TOWER PARTS FEEDER

The TS3AX is our standard TS2AX lifting tower, equipped with a horizontal single-axis gantry and a pneumatically operated arm.

The TS4AX, on the other hand, has a horizontal and vertical axis gantry to grip parts at different heights.

For both solutions, we can also provide the workpiece gripping end effector and related gripping fingers, dedicated to your parts.

These machines are the most suitable solution for separating the loading/unloading cycle from the palletizing or tending of other in-line peripherals units.

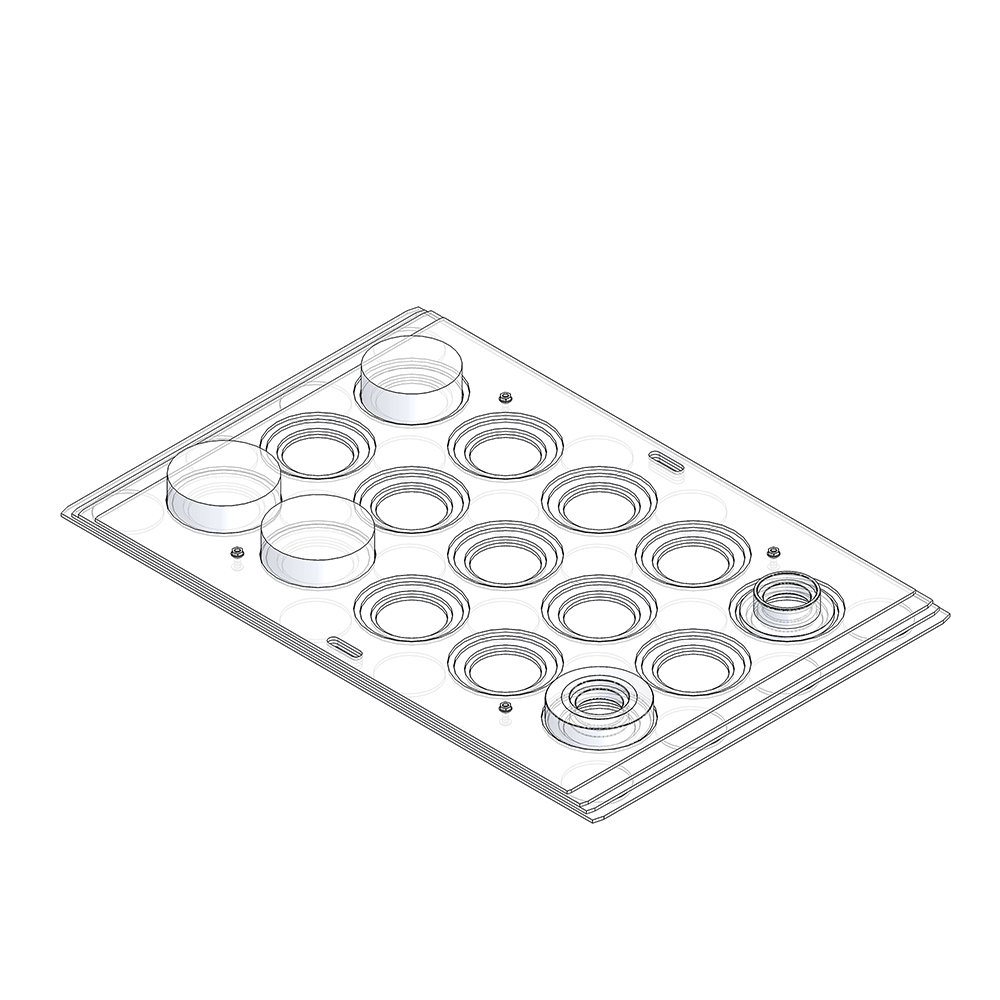

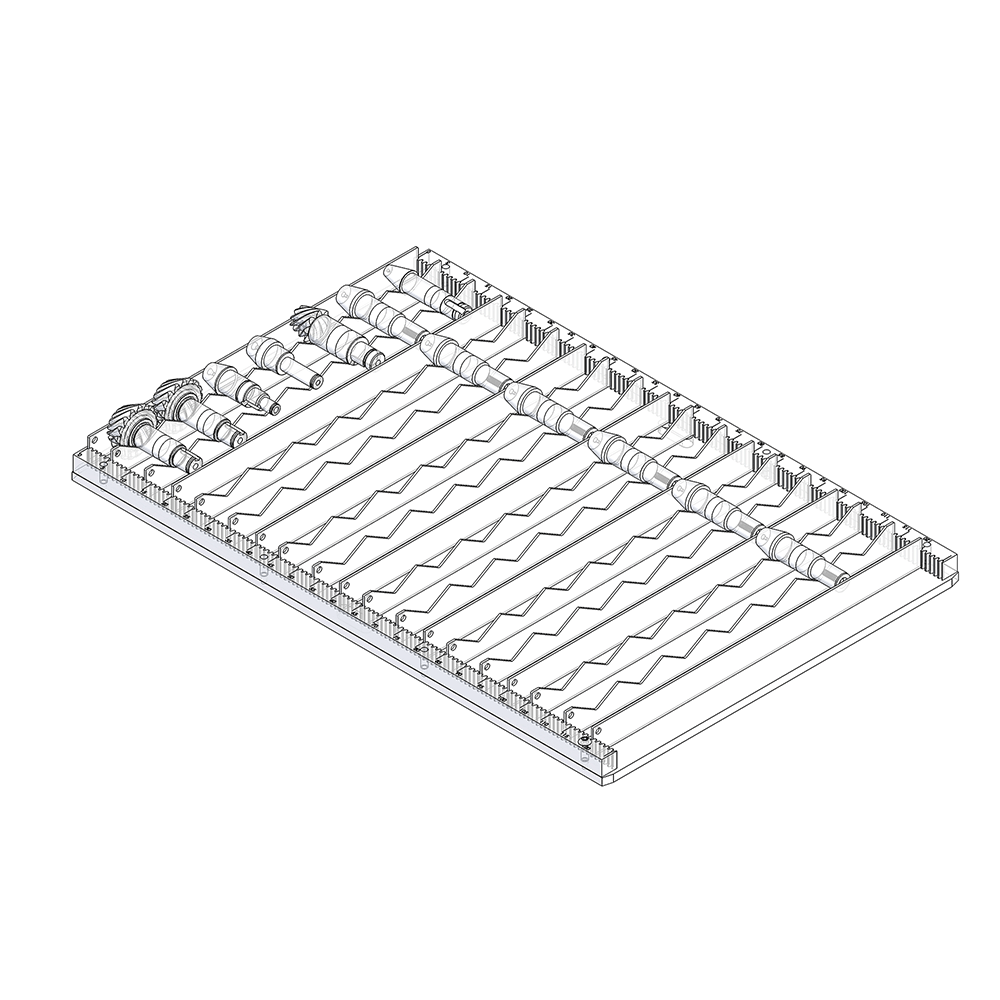

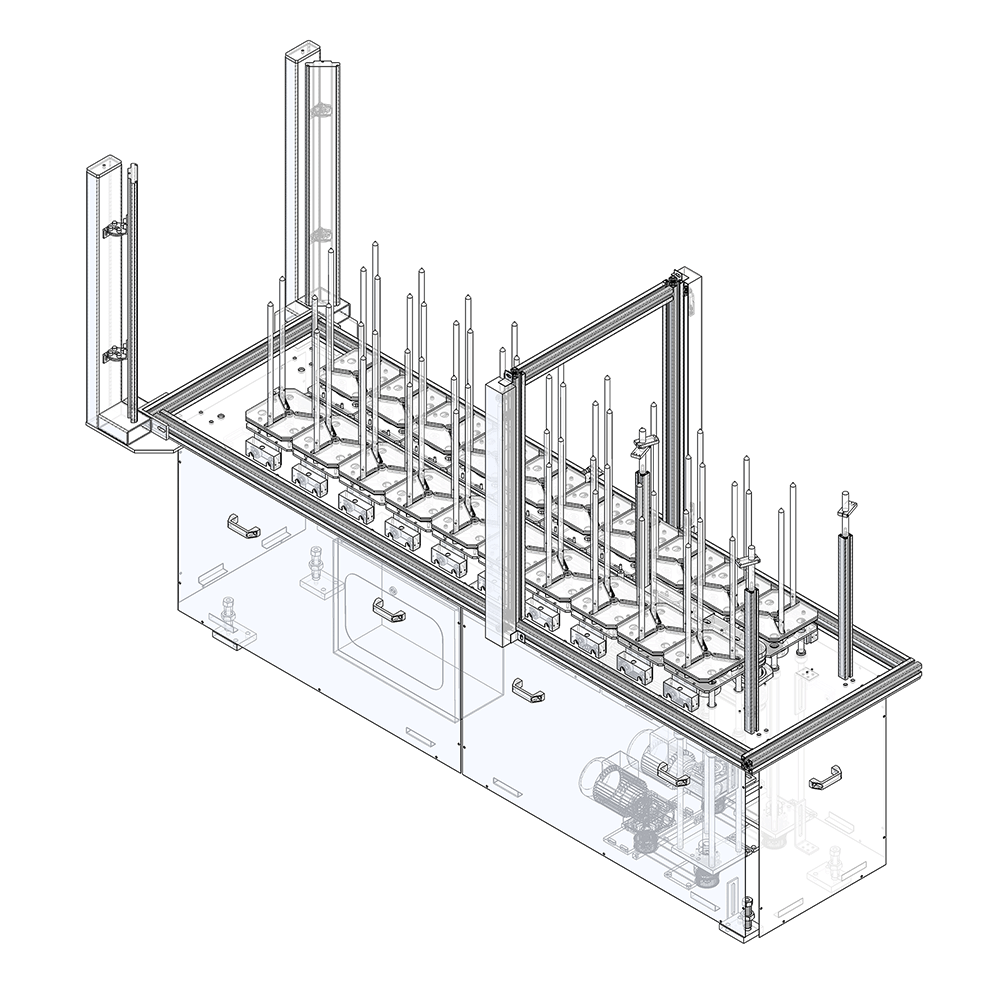

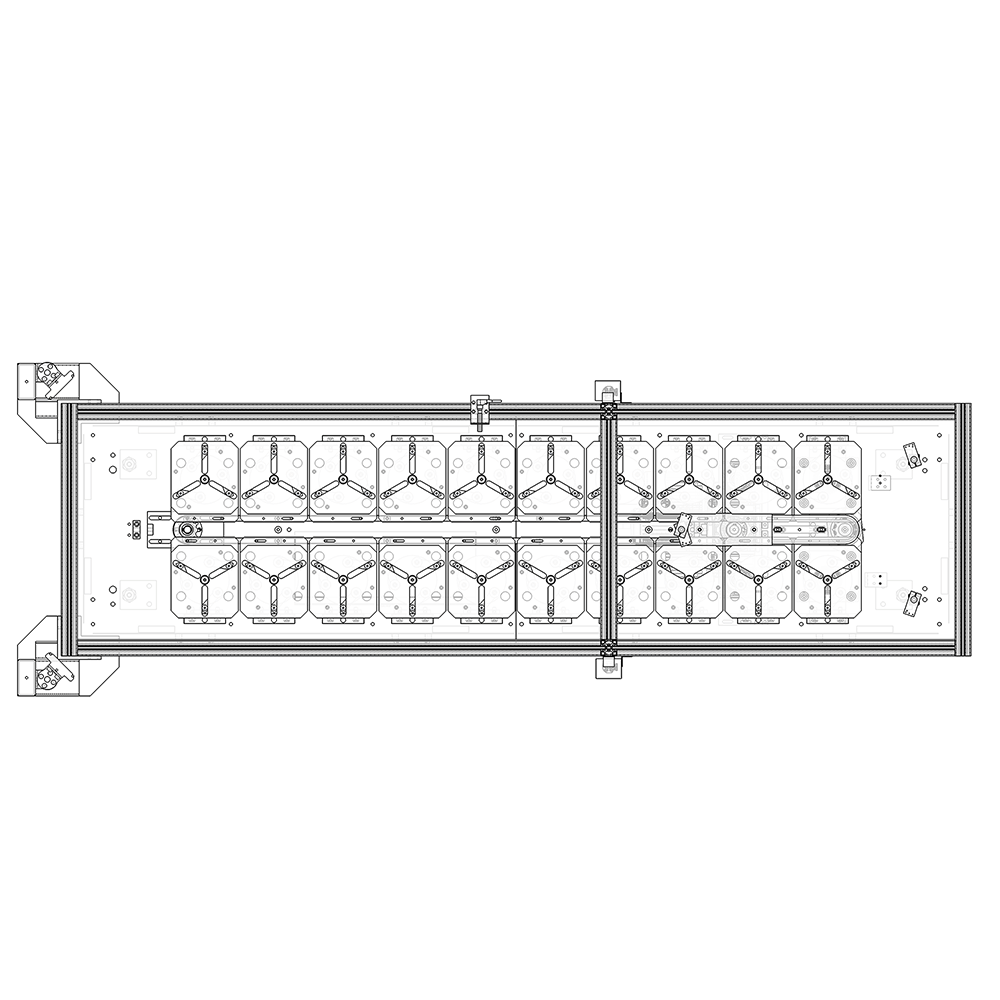

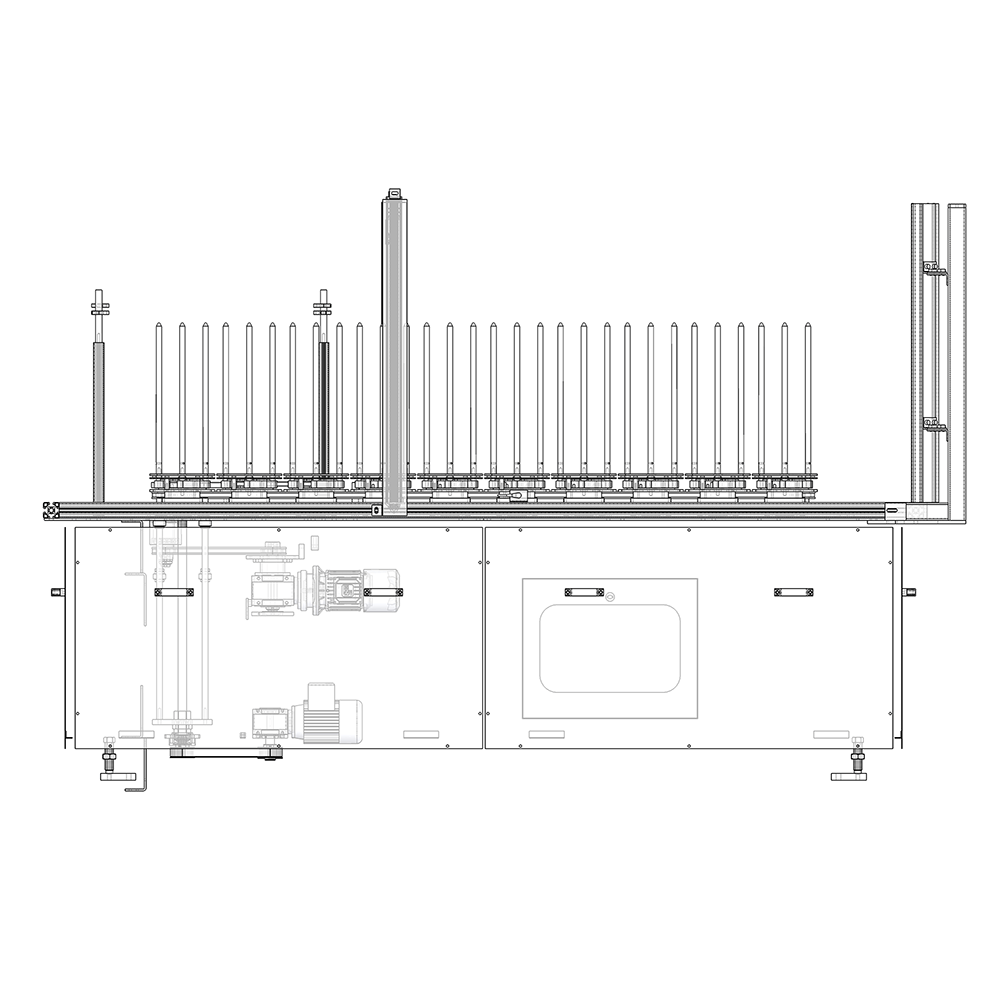

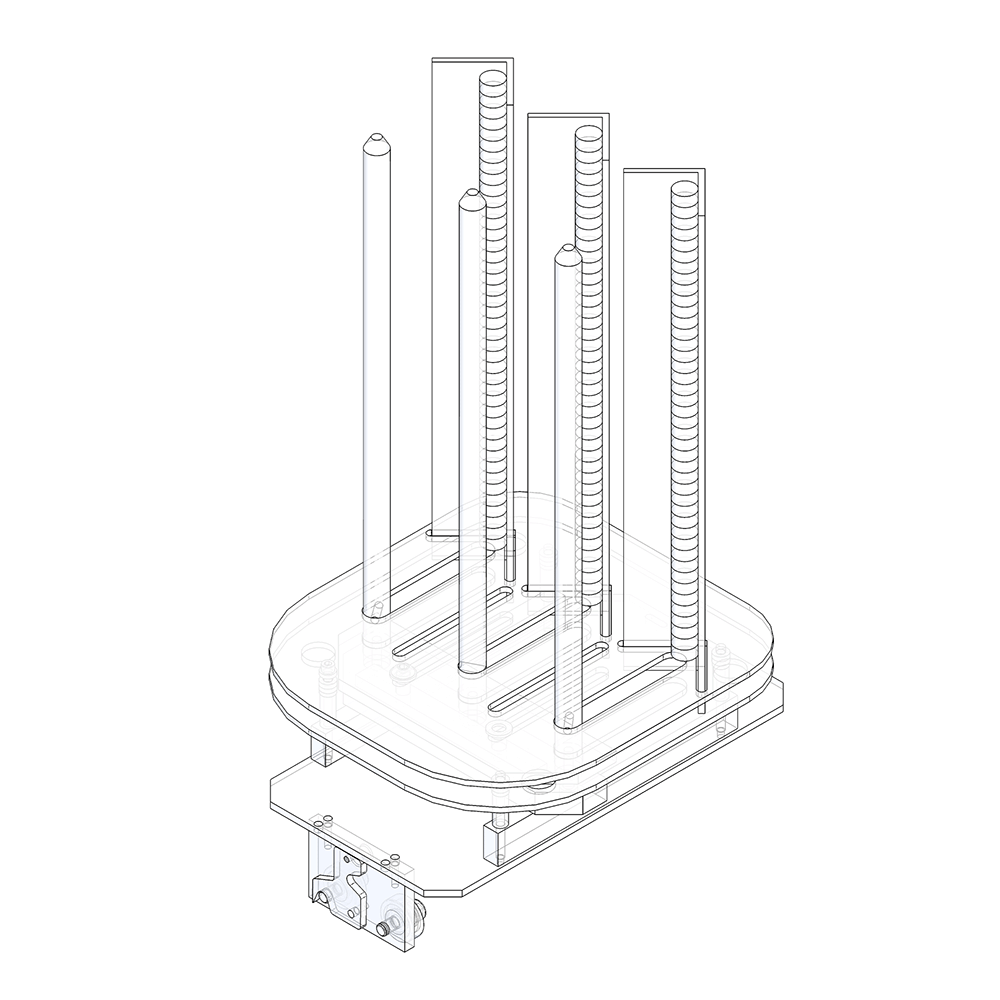

MRP PARTS FEEDER

The MRP part feeder is the best solution for flanged parts that may be stacked.

It is equipped with a step motor for pallet circulation and two electric pallet lifting and lowering devices in the pick and place positions.

The size and type of pallets may vary depending on the parts to be stacked.

Operation cycle management is performed by a plc with dedicated software.

MRP SIZES

For parts from diameter 30 mm up to:

– 170 – 185 mm – capacity 14 or 20 pallets

– 300 mm- capacity 14, 16 or 20 pallets

– 450 mm – capacity 20 pallets

– 600 mm- capacity 10 pallets

New projects can be evaluated upon request

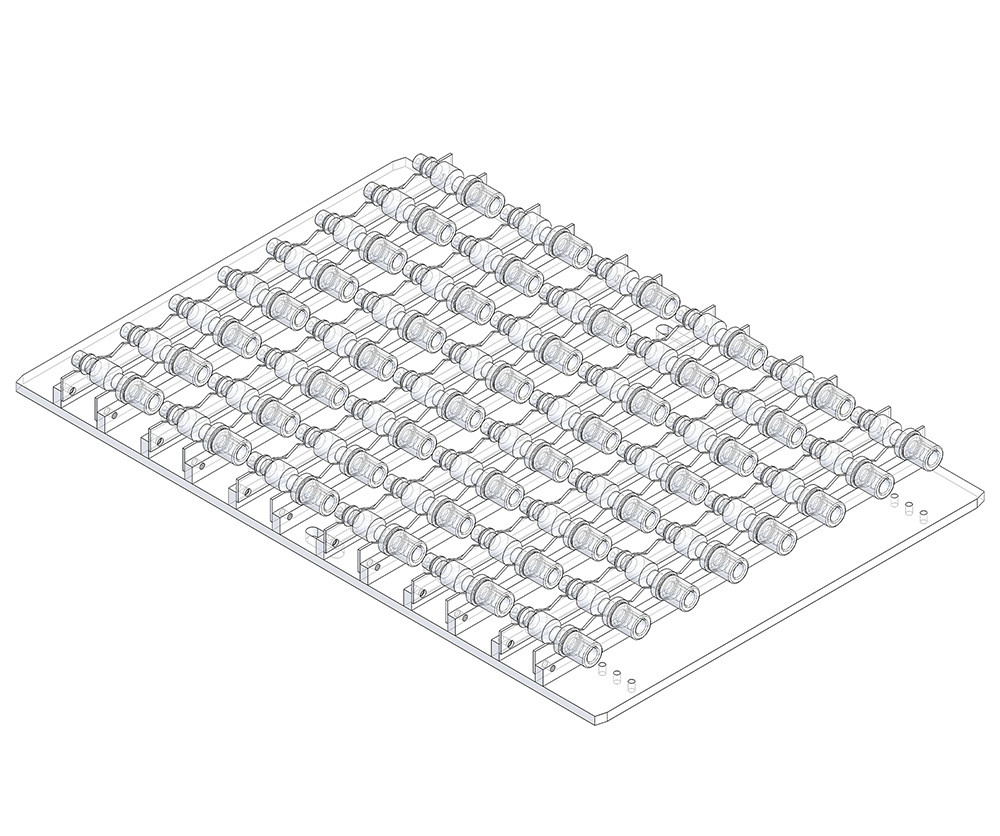

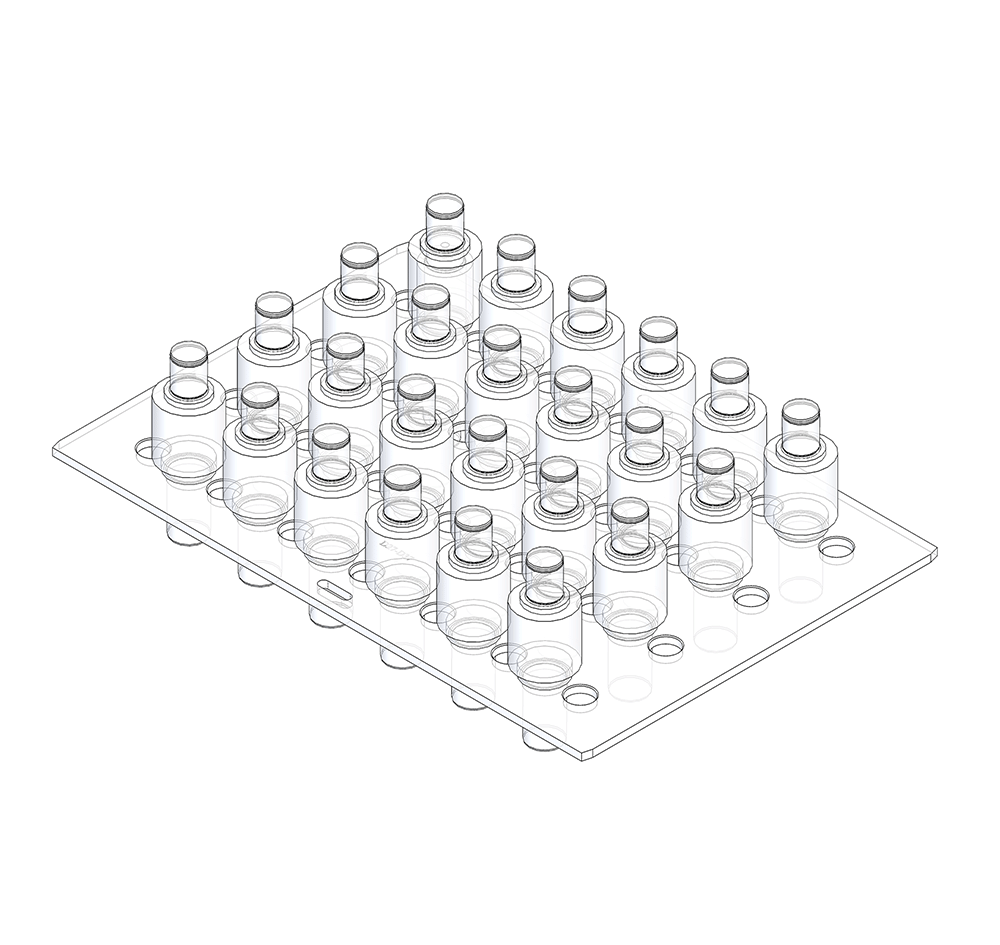

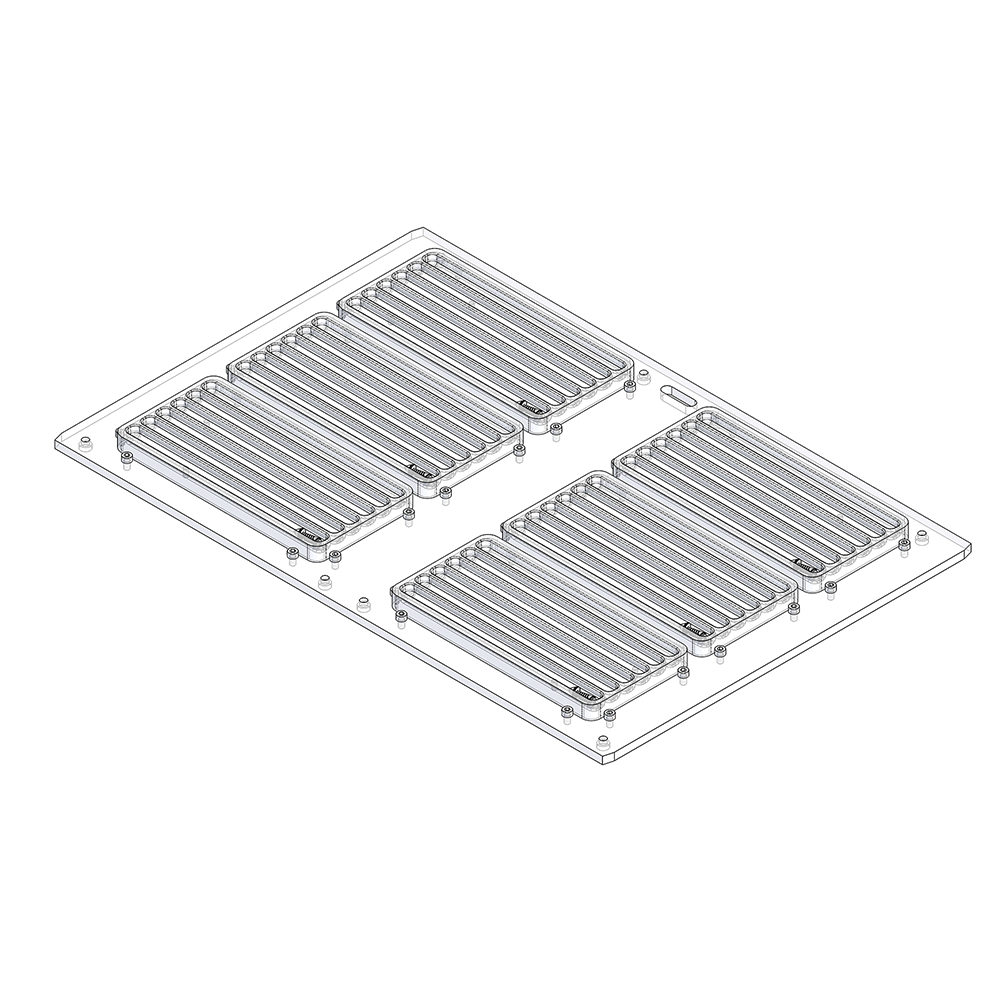

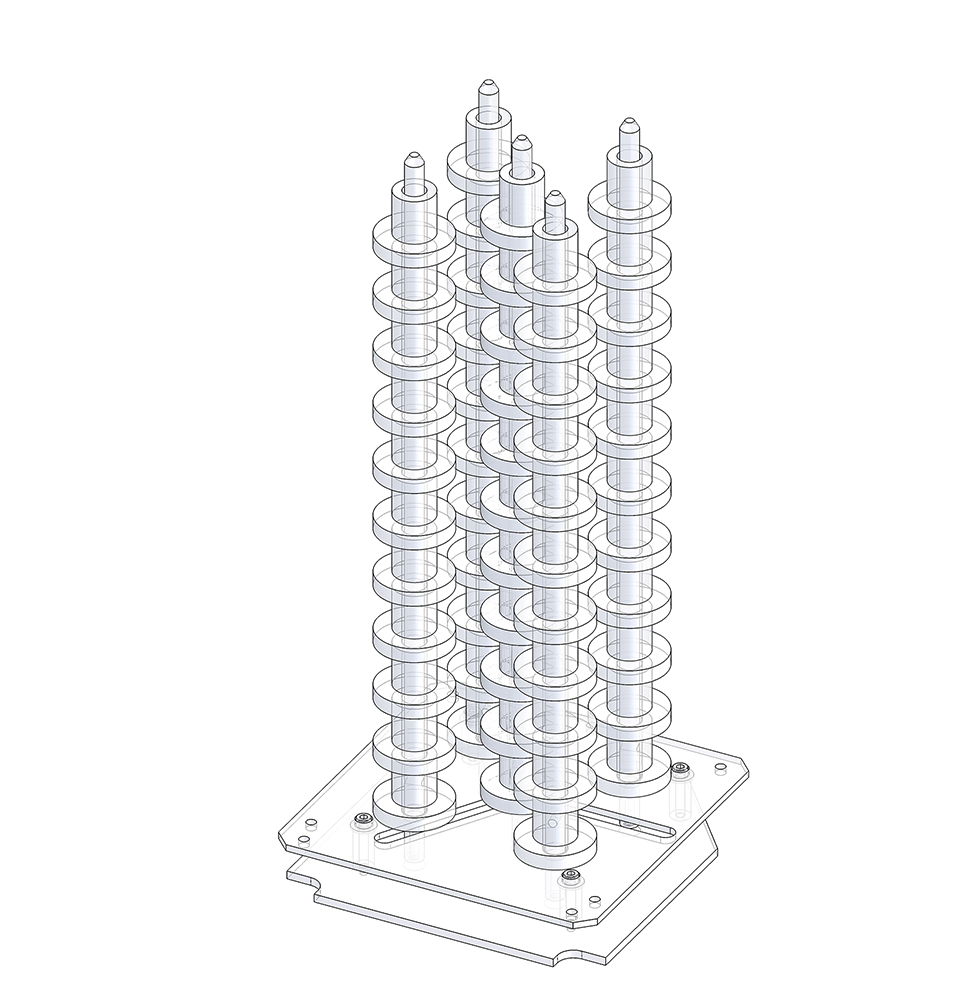

PALLET MRP

In the standard parts feeder, each pallet has 3 self-centering bars that can easily adapt to a wide range of diameters.

Pieces can be stacked along the full height of the bars (450 mm).

Thanks to our in-house design staff, we can provide various customizations for handling various types of parts, including shaft-like parts or non-stackable parts